-

Application Notes · 2024Year35Moon29Day

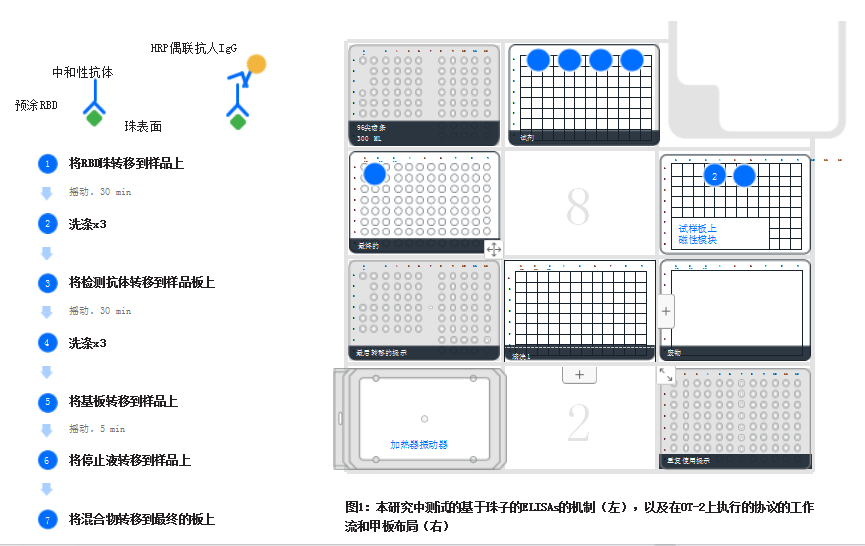

Automating neutralizing antibodies against SARS-CoV-2 using an on-deck heater-shaking module

Read More -

Application Notes · 2024Year19Moon29Day

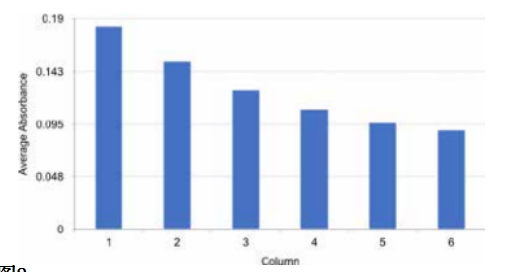

Perform serial dilutions on OT-2

Read More -

Application Notes · 2024Year9Moon29Day

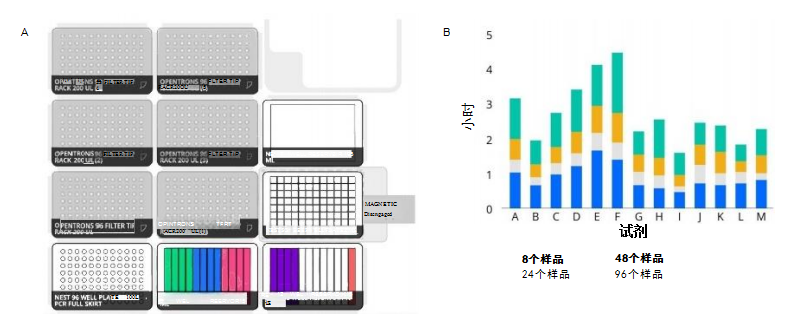

Efficient Nucleic Acid Extraction Using the OT-2 Automated Pipetting Platform

Read More

-

NEST single hole reservoir, 290 mL

-

NEST 2 mL 96 Deep Well Plate, V Bottom

-

NEST 96-well plate, flat bottom

-

NEST single hole reservoir, 195 mL

-

NEST 12-well reservoir, 15 mL

-

OT-2 32-well tube rack, 15mL

-

Opentrons 0.2 mL 96-well PCR rigid plate, fully skirted

-

NEST 50 mL centrifuge tube

-

NEST 15 mL centrifuge tube

-

NEST 2.0 mL centrifuge tube

-

NEST 1.5 mL centrifuge tube

-

Four-in-one centrifuge tube rack

-

Aluminum alloy pipe rack

-

OT-2 filter tip, 200μL

-

OT-2 filter tip, 1000μL

-

OT-2 Tip, 20μL

-

OT-2 Tip, 300μL

-

OT-2 Tip, 1000μL

-

OT-2 filter tip, 20μL

-

Opentrons Flex 96-channel tip rack adapter

-

Opentrons Flex Tips, 50 μL

-

Opentrons Flex Tips, 200 μL

-

Opentrons Flex Tips, 1000 μL

-

Opentrons Flex Filter Tips, 50 μL

-

Opentrons Flex Filter Tips, 1000 μL

-

Opentrons Flex Filter Tips, 200 μL